|

|

Air Station with Fridge Dryer Tank Mounted

Oil-Injected Air-Cooled Regulated Speed

Air demand in the working environment can vary widely throughout the day. CompAir offers now a complete range of speed regulated compressors from 7.5 to 250 kW. The L07-22 RS series of regulated speed compressors are able to precisely match power consumption with the system air demand, offering outstanding efficiency and reliability.

Large Size Air Compressor Fixed or Regulated Speed

Oil-Free Water Injected with RO System & Water Supply

Oilfree Scroll Compressor

Oil-Free Dry Screw The fully silenced, free-standing D-series compressor package includes drive motor, coolers, inlet filtration and silencing system, integrated compressor controls and all services connections. As a result installation requirements and associated costs are reduced. Design features:

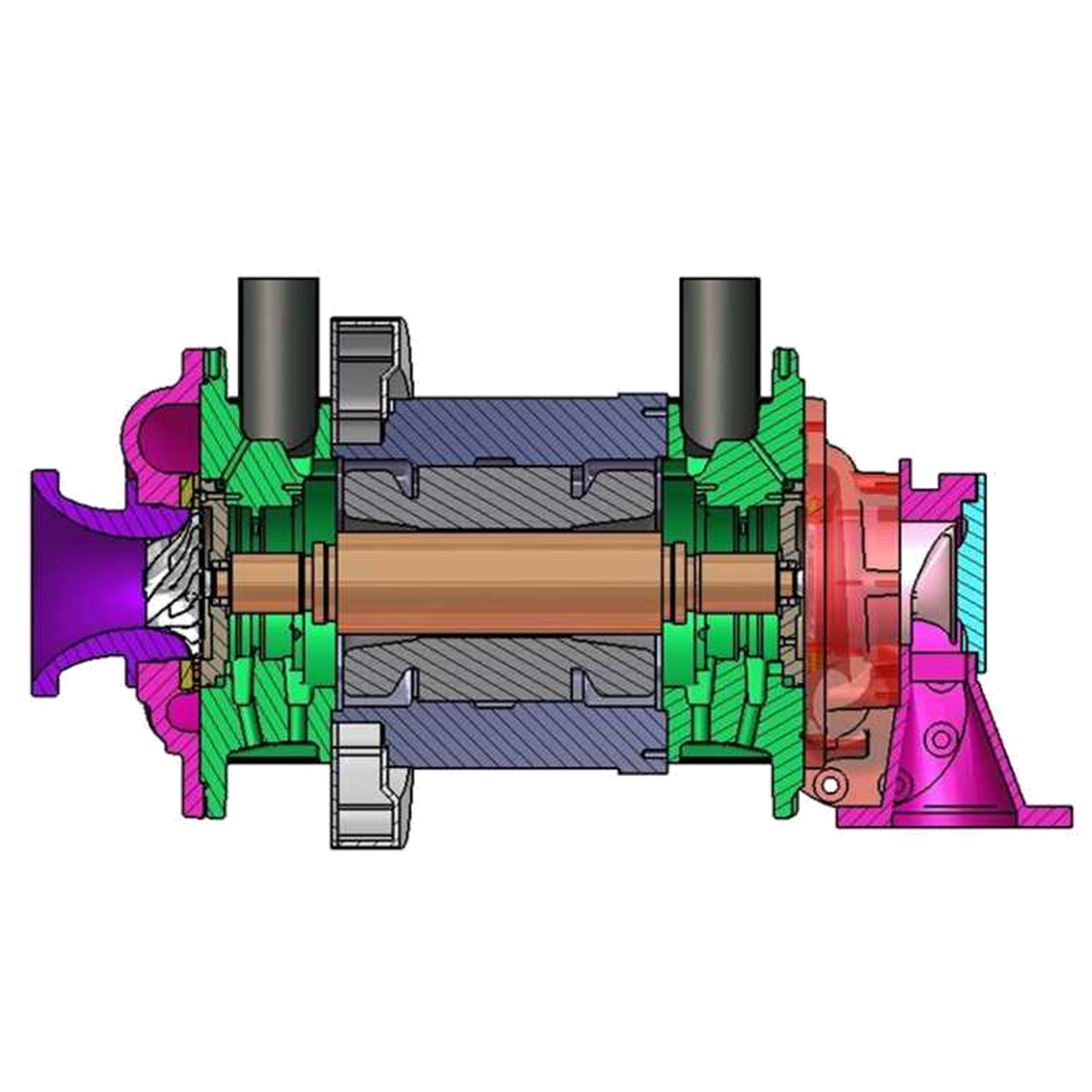

2 Stage High Speed, Direct Driven, Variable Speed The high frequency inverter variable speed drive acts as an electronic gearbox . Not only does it allow for the required high speeds for compression, it also provides variable speed operation to match compressor flow to plant demand and hence minimise power consumption Patented Q-Drive High Speed Motor, No Gearbox & Contact Quantima's patented Q-Drive and motor assembly has just one moving part and operates with the rotor spinning at a magnetic field at up to 60,000 rpm. This eliminates the costly gearbox losses and means that the compressor does not require any oil at all. Q-Drive is special for what t doesn't have

Lightweight Modular Acoustic Canopy The compressor is housed in a modular acoustic canopy with intelligent sound attenuation resulting in noise levels which are the lowest of any compressor in this class - just 69 dB(A). |